Product Description

Product Parameters

| Model | Power(Kw) | Free air delivery(m³/min) | Weight(kg) | Size(mm) | Pipe Diamater | ||||

| 0.3Mpa | 0.4MPa | 0.5MPa | Length | Width | Height | ||||

|

MQ37A/3 |

37 |

11.88 |

/ |

/ |

1170 |

2100 |

1250 |

1730 |

DN65 |

|

MQ37A/4 |

37 |

/ |

10.5 |

/ |

1170 |

2100 |

1250 |

1730 |

DN65 |

|

MQ37A/5 |

37 |

/ |

/ |

9.2 |

1170 |

2100 |

1250 |

1730 |

DN65 |

|

MQ45A/3 |

45 |

14 |

/ |

/ |

1185 |

2600 |

1650 |

2050 |

DN100 |

|

MQ45A/4 |

45 |

/ |

12.5 |

/ |

1185 |

2100 |

1250 |

1730 |

DN65 |

|

MQ45A/5 |

45 |

/ |

/ |

10.32 |

1185 |

2100 |

1250 |

1730 |

DN65 |

|

MQ55A/3 |

55 |

17.66 |

/ |

/ |

1185 |

2600 |

1650 |

2050 |

DN100 |

|

MQ55A/4 |

55 |

/ |

15.27 |

/ |

1185 |

2600 |

1500 |

1900 |

DN80 |

|

MQ55A/5 |

55 |

/ |

/ |

14.13 |

1185 |

2600 |

1500 |

1900 |

DN80 |

|

MQ75A/3 |

75 |

23.64 |

/ |

/ |

2280 |

2600 |

1650 |

2050 |

DN100 |

|

MQ75A/4 |

75 |

/ |

20.19 |

/ |

2280 |

2600 |

1500 |

1900 |

DN80 |

|

MQ75A/5 |

75 |

/ |

/ |

18.4 |

2280 |

2600 |

1500 |

1900 |

DN80 |

| MQ90A/3 | 90 | 29.63 | / | / | 3000 | 2900 | 1880 | 2080 | DN100 |

| MQ90A/4 | 90 | / | 24 | / | 3000 | 2700 | 1630 | 2100 | DN125 |

| MQ90A/5 | 90 | / | / | 21.25 | 3000 | 2700 | 1630 | 1900 | DN80 |

| MQ110A/3 | 110 | 35.77 | / | / | 3160 | 3000 | 2000 | 2280 | DN125 |

| MQ110A/4 | 110 | / | 29.69 | / | 3160 | 3000 | 2000 | 2280 | DN125 |

| MQ110A/5 | 110 | / | / | 28 | 3160 | 3000 | 2000 | 2280 | DN125 |

| MQ132A/3 | 132 | 40.27 | / | / | 4640 | 3000 | 2000 | 2280 | DN125 |

| MQ132A/4 | 132 | / | 35.62 | / | 4640 | 3000 | 2000 | 2280 | DN125 |

| MQ132A/5 | 132 | / | / | 30.5 | 4640 | 3000 | 2000 | 2280 | DN125 |

| MQ160A/3 | 160 | 50.1 | / | / | 4900 | 3600 | 2200 | 2280 | DN150 |

| MQ160A/4 | 160 | / | 47 | / | 4900 | 3600 | 2200 | 2280 | DN150 |

| MQ160A/5 | 160 | / | / | 42 | 4900 | 3600 | 2200 | 2280 | DN150 |

| MQ185A/3 | 185 | 61 | / | / | 5600 | 3800 | 2300 | 2400 | DN150 |

| MQ185A/4 | 185 | / | 50 | / | 5600 | 3800 | 2300 | 2400 | DN150 |

| MQ185A/5 | 185 | / | / | 45 | 5600 | 3800 | 2300 | 2400 | DN150 |

| MQ200A/3 | 200 | 63 | / | / | 5850 | 3800 | 2300 | 2400 | DN150 |

| MQ200A/4 | 200 | / | 57 | / | 5850 | 3800 | 2300 | 2400 | DN150 |

| MQ200A/5 | 200 | / | / | 51.5 | 5850 | 3800 | 2300 | 2400 | DN150 |

| MQ220A/3 | 220 | 65 | / | / | 6600 | 4000 | 2400 | 2600 | DN200 |

| MQ220A/4 | 220 | / | 62 | / | 6600 | 4000 | 2400 | 2600 | DN200 |

| MQ220A/5 | 220 | / | / | 55 | 6600 | 4000 | 2400 | 2600 | DN200 |

| MQ250A/3 | 250 | 67.5 | / | / | 6900 | 4000 | 2400 | 2600 | DN200 |

| MQ250A/4 | 250 | / | 65 | / | 6900 | 4000 | 2400 | 2600 | DN200 |

| MQ250A/5 | 250 | / | / | 61 | 6900 | 4000 | 2400 | 2600 | DN200 |

Installation Instructions

Operation Instructions:

A:Before Operation:

- Confirm the voltage of the power supply and the power indicator light is lit.

- Please open the leak valve of the oil & gas tank, drain the condensed water and immediately close the leak valve when oil leaks out.

- Please check the oil level and keep it between indicator oil level.

- Water cooled system , confirm that cooling water supply is normal.

- When generator driving the belt, please check the belt tension correctly, not too loose or too tight.

B:Start up

- Main power switch in.

- Press the start button to turn on the motor, working indicator light is on.

- Check the discharge pressure gauge and lubricating oil pressure gauge are in correct indication.

C:Operation

Please keep the exhaust temperature between 75ºC-95ºC to avoid condensation and precipitation and emulsify the oil.

D:Stop

- Press the “off” button, about 10-15 seconds later, the delay electromagnetic valve acts, and the compressor stops running.

- Turn off the power.

- Don’t use the emergency stop button in case of non emergency.

E: Precautions:

- For initial start-up and after motor maintenance, determine the running direction of the press (as indicated by the arrow).

- Do not mix different brand of river lubricating oil.

- Change the consumables, lubricating oil and detail operation method, please refer the instruction manual.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.webp)

Can Gas Air Compressors Be Used for Well Drilling?

Gas air compressors can be used for well drilling, and they are commonly employed in drilling operations. Here’s a detailed explanation:

1. Air Drilling Method:

Gas air compressors are often utilized in the air drilling method, also known as pneumatic drilling. In this drilling technique, compressed air is used to create a high-velocity airflow that carries the drill cuttings to the surface. The high-pressure air also aids in cooling the drill bit and providing additional force for efficient drilling.

2. Benefits of Gas Air Compressors:

Gas air compressors offer several advantages for well drilling:

- Portability: Gas air compressors can be easily transported to remote drilling sites, allowing for flexibility in well location.

- Power: Gas air compressors provide high-pressure air output, which is essential for effective drilling in various geological formations.

- Cost-Effectiveness: Gas air compressors can be more cost-effective compared to other drilling methods, as they eliminate the need for drilling mud and associated disposal costs.

- Environmental Considerations: Air drilling with gas compressors produces minimal waste and does not require the use of potentially harmful drilling fluids, making it an environmentally friendly option.

3. Compressor Selection:

When selecting a gas air compressor for well drilling, several factors should be considered:

- Pressure and Flow Requirements: Evaluate the pressure and flow requirements of the drilling operation to ensure that the gas air compressor can deliver the necessary air output.

- Compressor Size and Power: Choose a compressor with adequate size and power output to match the drilling demands. Factors such as borehole depth, drill bit type, and drilling speed will influence the compressor’s power requirements.

- Portability: Consider the portability features of the gas air compressor, such as its weight, dimensions, and mobility options, to facilitate transportation to drilling sites.

4. Safety Considerations:

It is essential to follow safety guidelines when using gas air compressors for well drilling. These may include proper ventilation to prevent the accumulation of exhaust fumes, adherence to equipment operating limits, and the use of personal protective equipment (PPE) for drilling personnel.

5. Other Considerations:

While gas air compressors are commonly used for well drilling, it is worth noting that the suitability of a gas air compressor for a specific drilling project depends on various factors such as geological conditions, well depth, and drilling objectives. It is recommended to consult with drilling experts and professionals to determine the most suitable drilling method and equipment for a particular project.

In summary, gas air compressors can be effectively used for well drilling, particularly in the air drilling method. They offer portability, power, cost-effectiveness, and environmental advantages. Proper selection, considering pressure and flow requirements, as well as safety precautions, is crucial to ensure successful and safe drilling operations.

.webp)

Can Gas Air Compressors Be Used for Pneumatic Tools?

Yes, gas air compressors can be used for pneumatic tools. Here’s a detailed explanation:

1. Versatile Power Source:

Gas air compressors, powered by gasoline or diesel engines, provide a portable and versatile power source for operating pneumatic tools. They eliminate the need for electrical power supply, making them suitable for remote locations or construction sites where electricity may not be readily available.

2. High Power Output:

Gas air compressors typically offer higher power output compared to electric compressors of similar size. This high power output enables gas compressors to deliver the necessary air pressure and volume required by pneumatic tools, ensuring optimal tool performance.

3. Mobility and Portability:

Gas air compressors are often designed with mobility and portability in mind. They are compact and equipped with wheels or handles, allowing for easy transportation to different job sites. This mobility is advantageous when using pneumatic tools in various locations or when working in confined spaces.

4. Continuous Operation:

Gas air compressors can provide continuous air supply for pneumatic tools without the need for frequent pauses or recharging. As long as there is an adequate fuel supply, gas compressors can operate for extended periods, allowing uninterrupted use of pneumatic tools for tasks such as drilling, nailing, sanding, or painting.

5. Suitable for High-Demand Applications:

Pneumatic tools used in heavy-duty applications often require a robust air supply to meet their performance requirements. Gas air compressors can generate higher air flow rates and maintain higher operating pressures, making them suitable for high-demand pneumatic tools like jackhammers, impact wrenches, or sandblasters.

6. Flexibility in Compressor Size:

Gas air compressors are available in various sizes and capacities, allowing users to choose the compressor that best matches the air demands of their pneumatic tools. From small portable compressors for light-duty tasks to larger industrial-grade compressors for heavy-duty applications, there is a wide range of options to suit different tool requirements.

7. Reduced Dependency on Electrical Infrastructure:

Using gas air compressors for pneumatic tools reduces reliance on electrical infrastructure. In situations where the electrical power supply is limited, unreliable, or expensive, gas compressors offer a viable alternative, ensuring consistent tool performance without concerns about power availability.

It’s important to note that gas air compressors emit exhaust gases during operation, so proper ventilation is necessary when using them in enclosed spaces to ensure the safety of workers.

In summary, gas air compressors can effectively power pneumatic tools, offering mobility, high power output, continuous operation, and suitability for various applications. They provide a reliable and portable solution for utilizing pneumatic tools in locations where electrical power supply may be limited or unavailable.

.webp)

What Industries Commonly Use Gas Air Compressors?

Gas air compressors find applications in various industries where compressed air is required for powering tools, equipment, and systems. These compressors are valued for their portability, versatility, and ability to provide high-pressure air. Here’s a detailed explanation of the industries that commonly use gas air compressors:

1. Construction Industry:

The construction industry extensively utilizes gas air compressors for a wide range of tasks. Compressed air is used to power pneumatic tools such as jackhammers, nail guns, impact wrenches, and concrete breakers. Gas air compressors provide the necessary airflow and pressure to operate these tools efficiently, making them ideal for construction sites.

2. Mining Industry:

In the mining industry, gas air compressors play a vital role in various operations. Compressed air is used to power pneumatic tools for drilling, rock blasting, and excavation. It is also employed in ventilation systems, conveying systems, and pneumatic control devices in mines. Gas air compressors are valued for their durability and ability to operate in rugged and remote mining environments.

3. Oil and Gas Industry:

The oil and gas industry relies on gas air compressors for numerous applications. They are used for well drilling operations, powering pneumatic tools, and maintaining pressure in oil and gas pipelines. Gas air compressors are also utilized in natural gas processing plants, refineries, and petrochemical facilities for various pneumatic processes and equipment.

4. Manufacturing and Industrial Sector:

In the manufacturing and industrial sector, gas air compressors are extensively used in different applications. They provide compressed air for pneumatic tools, such as air-powered drills, sanders, grinders, and spray guns. Compressed air is also used in manufacturing processes such as material handling, assembly line operations, and pneumatic control systems.

5. Automotive Industry:

The automotive industry utilizes gas air compressors for a variety of tasks. Compressed air is employed in automotive assembly plants for pneumatic tools, paint spraying booths, and pneumatic control systems. Gas air compressors are also used in auto repair shops for powering air tools, tire inflation, and operating pneumatic lifts.

6. Agriculture and Farming:

Gas air compressors have applications in the agriculture and farming sector. They are used for tasks such as powering pneumatic tools for crop irrigation, operating pneumatic seeders or planters, and providing compressed air for farm maintenance and repair work. Portable gas air compressors are particularly useful in agricultural settings where electricity may not be readily available.

7. Food and Beverage Industry:

In the food and beverage industry, gas air compressors are employed for various pneumatic processes and equipment. They are used in food packaging operations, pneumatic conveying systems for ingredients and finished products, and air-powered mixing and blending processes. Gas air compressors in this industry are designed to meet strict hygiene and safety standards.

8. Pharmaceutical and Healthcare Sector:

The pharmaceutical and healthcare sector utilizes gas air compressors for critical applications. Compressed air is used in medical devices, dental equipment, laboratory instruments, and pharmaceutical manufacturing processes. Gas air compressors in this industry must adhere to stringent quality standards and maintain air purity.

These are just a few examples of the industries that commonly use gas air compressors. Other sectors, such as power generation, aerospace, marine, and chemical industries, also rely on gas air compressors for specific applications. The versatility and reliability of gas air compressors make them indispensable in numerous industries where compressed air is a vital resource.

<img src="https://img.hzpt.com/img/air-compressor/air-compressor-L1.webp" alt="China wholesaler Best-Selling Medium and Low Pressure Price China Single-Stage Drive Gas Screw Air Compressor air compressor for car”><img src="https://img.hzpt.com/img/air-compressor/air-compressor-L2.webp" alt="China wholesaler Best-Selling Medium and Low Pressure Price China Single-Stage Drive Gas Screw Air Compressor air compressor for car”>

editor by lmc 2024-10-21

China OEM Efficient Nitrogen Air Compressor Booster 150 Bar 200 Bar Gas Booster with high quality

Product Description

| specifications | ZW-60/4-15 | ||||||||||||||

| Exhaust volume | 60Nm ³/ h | ||||||||||||||

| Power(KW) | 7.5 | ||||||||||||||

| Intake pressure (Mpa) |

0.4 | ||||||||||||||

| Exhaust pressure (Mpa) |

1.5 | ||||||||||||||

| External dimensions | 1150*650*980 | ||||||||||||||

| noise dB |

73±2 | ||||||||||||||

| weight (KG) |

260 | ||||||||||||||

| outlet size | R1″ | ||||||||||||||

| Cooling method | Air cooling | ||||||||||||||

More recommended products,click on the image to view

HangZhou CHINAMFG Oil Free Compressor Co., Ltd. was established in 2016. The factory is located in the famous oil free compressor production base in China (HangZhou), providing safe and reliable medical grade 0 oil free vortex air compressors to meet various application industries, including medical gas, pharmaceuticals, food and beverage, cosmetics, electronic industry, chemical industry, laboratory, biological fermentation, environmental protection, and other general industries.

Why choose CHINAMFG air compressor

1.Products have past the German TUV classo, IP67, EMC and salt spray test certification.

2.Oil free, to avoid oil leakage problem completely and oil in the compressed ai.

3.Avoid regularly clean oil discharge and waste oil processing of environmental protection, to achieve zero emissions.

4.Continuous scroll, high efficiency , low energy consumption.

5.Easy maintenance, less time consuming, it only takes 2 hours each year for preventive maintenance.

6.Failure rate is low, without oil emulsification phenomenon, maintenance is convenient and simple.

7.Dynamic and static scroll does not contact during working, low vibration, low noise.

8.Scroll air end has simple structure, less parts, less wearing parts, greatly reduces the possibility replacing parts, with high durability.Robust structure design high quality air supply capa bitity can improve reliability

Machine Parts

| Serial Number | specifications | Exhaust volume m ³/ min | Power(KW) | pressure (Mpa) |

External dimensions | host (Pcs) |

noise dB |

weight (KG) |

outlet size |

notes |

| 1 | HK-D04/08-S1 | 0.4 | 3.7 | 08./1.0 | 730*610*880 | 1*04 | 55±2 | 200 | 3/4ball valve | box-type |

| 2 | HK-D04/08-J3 | 0.4 | 3.7 | 08./1.0 | 1300*840*1480 | 1*04 | 55±2 | 300 | 3/4ball valve | External integrated

200L |

| 3 | HK-D04/08-S2 | 0.4 | 3.7 | 08./1.0 | 1000*700*1500 | 1*4 | 55±2 | 350 | 3/4ball valve | Built in integrated

50L |

| 4 | HK-D06/08-S1 | 0.6 | 5.5 | 08./1.0 | 730*610*880 | 1*06 | 58±2 | 210 | 3/4ball valve | box-type |

| 5 | HK-D06/08-J3 | 0.6 | 5.5 | 08./1.0 | 1300*840*1480 | 1*06 | 58±2 | 310 | 3/4ball valve | External integrated

200L |

| 6 | HK-D06/08-S2 | 0.6 | 5.5 | 08./1.0 | 1000*700*1500 | 1*06 | 58±2 | 360 | 3/4ball valve | Built in integrated

50L |

| 7 | HK-Q08/08-S1 | 0.8 | 7.5 | 08./1.0 | 1170*700*1080 | 2*04 | 60±2 | 380 | 1″ | box-type |

| 8 | HK-Q08/08-J7 | 0.8 | 7.5 | 08./1.0 | 1755*840*1640 | 2*04 | 60±2 | 480 | 1″ | External integrated

200L |

| 9 | HK-Q08/08-J8 | 0.8 | 7.5 | 08./1.0 | 1700*800*1700 | 2*04 | 60±2 | 500 | 1″ | Built in integrated

200L |

| 10 | HK-Z12/08-S1 | 1.2 | 11 | 08./1.0 | 1170*700*1080 | 2*06 | 62±2 | 400 | 1″ | box-type |

| 11 | HK-Z12/08-J7 | 1.2 | 11 | 08./1.0 | 1755*840*1640 | 2*06 | 62±2 | 500 | 1″ | External integrated

200L |

| 12 | HK-Z12/08-J8 | 1.2 | 11 | 08./1.0 | 1700*800*1700 | 2*06 | 62±2 | 550 | 1″ | Built in integrated

200L |

| 13 | HK-Q16/08-S1 | 1.6 | 15 | 08./1.0 | 1100x700x1750 | 4*04 | 65±2 | 500 | 1″ | box-type |

| 14 | HK-Z18/08-S1 | 1.8 | 16.5 | 08./1.0 | 1170*700*1550 | 3*06 | 65±2 | 600 | 1″ | box-type |

| 15 | HK-Z24/08-S1 | 2.4 | 22 | 08./1.0 | 1550*1140*1075 | 4*06 | 68±2 | 800 | 1.5″ | box-type |

| 16 | HK-Z30/08-S1 | 3 | 27.5 | 08./1.0 | 1550*1140*1550 | 5*06 | 70±2 | 1080 | 1.5″ | box-type |

| 17 | HK-Z36/08-S1 | 3.6 | 33 | 08./1.0 | 1550*1140*1550 | 6*06 | 70±2 | 1200 | 1.5″ | box-type |

| 18 | HK-Z42/08-S1 | 4.2 | 38.5 | 08./1.0 | 2150*1450*15800 | 7*06 | 72±2 | 1400 | 2.0″ | box-type |

| 19 | HK-Z48/08-S1 | 4.8 | 44 | 08./1.0 | 2150*1450*1580 | 8*06 | 72±2 | 1500 | 2.0″ | box-type |

| 20 | HK-Z54/08-S1 | 5.4 | 49.5 | 08./1.0 | 2150*1450*1580 | 9*06 | 72±2 | 1650 | 2.0″ | box-type |

FAQ

Q1: Are you factory or trade company?

A1: We are factory.

Q2: What the exactly address of your factory?

A2: Our factory is located in Jiabao Industrial Park, HangZhou City, ZheJiang Province, China

Q3: Warranty terms of your machine?

A3: One year warranty for the machine and technical support according to your needs.

Q4: Will you provide some spare parts of the machines?

A4: Yes, of course.

Q5:Are you support customization

A5:Yes, supported

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.webp)

Can Gas Air Compressors Be Used in Construction Projects?

Gas air compressors are widely used in construction projects due to their portability, versatility, and ability to provide the necessary compressed air for various applications. They are an essential tool in the construction industry, enabling the efficient and effective operation of pneumatic tools and equipment. Here’s a detailed explanation of how gas air compressors are used in construction projects:

1. Powering Pneumatic Tools:

Gas air compressors are commonly used to power a wide range of pneumatic tools on construction sites. These tools include jackhammers, nail guns, impact wrenches, concrete breakers, air drills, sanders, grinders, and paint sprayers. The compressed air generated by the gas air compressor provides the necessary force and power for efficient operation of these tools, enabling tasks such as concrete demolition, fastening, surface preparation, and finishing.

2. Air Blow and Cleaning Operations:

In construction projects, there is often a need to clean debris, dust, and dirt from work areas, equipment, and surfaces. Gas air compressors are used to generate high-pressure air for air blow and cleaning operations. This helps maintain cleanliness, remove loose materials, and prepare surfaces for further work, such as painting or coating.

3. Operating Pneumatic Systems:

Gas air compressors are employed to operate various pneumatic systems in construction projects. These systems include pneumatic control devices, pneumatic cylinders, and pneumatic actuators. Compressed air from the gas air compressor is used to control the movement of equipment, such as gates, doors, and barriers, as well as to operate pneumatic lifts, hoists, and other lifting mechanisms.

4. Concrete Spraying and Shotcreting:

Gas air compressors are utilized in concrete spraying and shotcreting applications. Compressed air is used to propel the concrete mixture through a nozzle at high velocity, ensuring proper adhesion and distribution on surfaces. This technique is commonly employed in applications such as tunnel construction, slope stabilization, and repair of concrete structures.

5. Sandblasting and Surface Preparation:

In construction projects that require surface preparation, such as removing old paint, rust, or coatings, gas air compressors are often used in conjunction with sandblasting equipment. Compressed air powers the sandblasting process, propelling abrasive materials such as sand or grit onto the surface to achieve effective cleaning and preparation before applying new coatings or finishes.

6. Tire Inflation and Equipment Maintenance:

Gas air compressors are utilized for tire inflation and equipment maintenance on construction sites. They provide compressed air for inflating and maintaining proper tire pressure in construction vehicles and equipment. Additionally, gas air compressors are used for general equipment maintenance, such as cleaning, lubrication, and powering pneumatic tools for repair and maintenance tasks.

7. Portable and Remote Operations:

Gas air compressors are particularly beneficial in construction projects where electricity may not be readily available or feasible. Portable gas air compressors provide the flexibility to operate in remote locations, allowing construction crews to utilize pneumatic tools and equipment without relying on a fixed power source.

Gas air compressors are an integral part of construction projects, facilitating a wide range of tasks and enhancing productivity. Their ability to power pneumatic tools, operate pneumatic systems, and provide compressed air for various applications makes them essential equipment in the construction industry.

.webp)

Can Gas Air Compressors Be Used for Natural Gas Compression?

Gas air compressors are not typically used for natural gas compression. Here’s a detailed explanation:

1. Different Compressed Gases:

Gas air compressors are specifically designed to compress atmospheric air. They are not typically designed or suitable for compressing natural gas. Natural gas, which is primarily composed of methane, requires specialized compressors designed to handle the unique properties and characteristics of the gas.

2. Safety Considerations:

Natural gas compression involves handling a flammable and potentially hazardous substance. Compressing natural gas requires specialized equipment that meets stringent safety standards to prevent leaks, minimize the risk of ignition or explosion, and ensure the safe handling of the gas. Gas air compressors may not have the necessary safety features or materials to handle natural gas safely.

3. Equipment Compatibility:

Natural gas compression systems typically include components such as gas compressors, gas coolers, separators, and control systems that are specifically designed and engineered for the compression and handling of natural gas. These components are built to withstand the specific demands and conditions associated with natural gas compression, including the high pressures and potential presence of impurities.

4. Efficiency and Performance:

Compressing natural gas requires specialized compressors that can handle the high-pressure ratios and volumetric flow rates associated with the gas. Gas air compressors are generally not designed to achieve the same compression ratios and performance levels required for natural gas compression. Using gas air compressors for natural gas compression would likely result in inefficient operation and suboptimal performance.

5. Regulatory Compliance:

Compressing natural gas is subject to various regulations and standards to ensure safety, environmental protection, and compliance with industry guidelines. These regulations often dictate specific requirements for equipment, materials, and operating procedures in natural gas compression systems. Gas air compressors may not meet these regulatory requirements for natural gas compression.

6. Industry Standards and Practices:

The natural gas industry has well-established standards and best practices for equipment selection, installation, and operation in gas compression systems. These standards are based on the specific requirements and characteristics of natural gas. Gas air compressors do not align with these industry standards and practices, which are essential for safe and efficient natural gas compression.

In summary, gas air compressors are not suitable for natural gas compression. Natural gas compression requires specialized equipment designed to handle the unique properties and safety considerations associated with the gas. Compressors specifically engineered for natural gas compression offer the necessary performance, safety features, and regulatory compliance required for efficient and reliable operation in natural gas compression systems.

.webp)

Can Gas Air Compressors Be Used in Remote Locations?

Yes, gas air compressors are well-suited for use in remote locations where access to electricity may be limited or unavailable. Their portability and reliance on gas engines make them an ideal choice for providing a reliable source of compressed air in such environments. Here’s a detailed explanation of how gas air compressors can be used in remote locations:

1. Independence from Electrical Grid:

Gas air compressors do not require a direct connection to the electrical grid, unlike electric air compressors. This independence from the electrical grid allows gas air compressors to be used in remote locations, such as wilderness areas, remote job sites, or off-grid locations, where it may be impractical or cost-prohibitive to establish electrical infrastructure.

2. Mobility and Portability:

Gas air compressors are designed to be portable and easy to transport. They are often equipped with handles, wheels, or trailers, making them suitable for remote locations. The gas engine powering the compressor provides mobility, allowing the compressor to be moved to different areas within the remote location as needed.

3. Fuel Versatility:

Gas air compressors can be fueled by various types of combustible gases, including gasoline, diesel, natural gas, or propane. This fuel versatility ensures that gas air compressors can adapt to the available fuel sources in remote locations. For example, if gasoline or diesel is readily available, the gas air compressor can be fueled with these fuels. Similarly, if natural gas or propane is accessible, the compressor can be configured to run on these gases.

4. On-Site Power Generation:

In remote locations where electricity is limited, gas air compressors can serve as on-site power generators. They can power not only the compressor itself but also other equipment or tools that require electricity for operation. This versatility makes gas air compressors useful for a wide range of applications in remote locations, such as powering lights, tools, communication devices, or small appliances.

5. Off-Grid Operations:

Gas air compressors enable off-grid operations, allowing tasks and activities to be carried out in remote locations without relying on external power sources. This is particularly valuable in industries such as mining, oil and gas exploration, forestry, or construction, where operations may take place in remote and isolated areas. Gas air compressors provide the necessary compressed air for pneumatic tools, drilling equipment, and other machinery required for these operations.

6. Emergency Preparedness:

Gas air compressors are also beneficial for emergency preparedness in remote locations. In situations where natural disasters or emergencies disrupt the power supply, gas air compressors can provide a reliable source of compressed air for essential equipment and systems. They can power emergency lighting, communication devices, medical equipment, or backup generators, ensuring operational continuity in critical situations.

7. Adaptability to Challenging Environments:

Gas air compressors are designed to withstand various environmental conditions, including extreme temperatures, humidity, dust, and vibrations. This adaptability to challenging environments makes them suitable for use in remote locations, where environmental conditions may be harsh or unpredictable.

Overall, gas air compressors can be effectively used in remote locations due to their independence from the electrical grid, mobility, fuel versatility, on-site power generation capabilities, suitability for off-grid operations, emergency preparedness, and adaptability to challenging environments. These compressors provide a reliable source of compressed air, enabling a wide range of applications in remote settings.

<img src="https://img.hzpt.com/img/air-compressor/air-compressor-L1.webp" alt="China OEM Efficient Nitrogen Air Compressor Booster 150 Bar 200 Bar Gas Booster with high quality”><img src="https://img.hzpt.com/img/air-compressor/air-compressor-L2.webp" alt="China OEM Efficient Nitrogen Air Compressor Booster 150 Bar 200 Bar Gas Booster with high quality”>

editor by lmc 2024-10-08

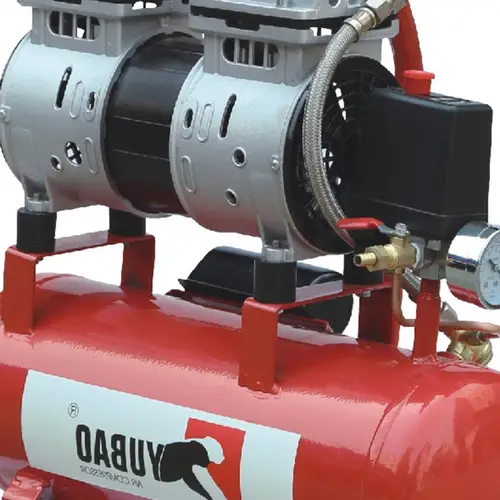

China wholesaler Convenient Energy Saving 100L 3HP Liter Air Compressor Tire Car Industrial Large Belt Gas Air Compressor in China air compressor portable

Product Description

ABOUT CHINAMFG

CHINAMFG GROUP is a large scale enterpise group which is specializing and manufacturing various kind of compressors, welding machines, motors and water pumps.

It was established in 1988. The headquarter is located in HangZhou City, HangZhou, ZHangZhoug Province. With modern factories covering areas more than 2 sets, covering 23 series and 120 kinds of specifications.

Since its establishment, we have always abode by the spirit of faithful and professional, pragmatic and innovation. We took in lead in introducing the ERP information management system. Making the management more innovative and perfect. In additional, our product has passed CE, ETL, RoHs, SAA and IS900A ect. The products have been covered all round of the world gain recognition from international customers!

This is our V type air compressor, it has 2 cylinder and the air pumping is faster than normal model, if you need help, just contact us

This air compressor is our best seller, it is portable and of great quality. /* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.webp)

Can Gas Air Compressors Be Used in Construction Projects?

Gas air compressors are widely used in construction projects due to their portability, versatility, and ability to provide the necessary compressed air for various applications. They are an essential tool in the construction industry, enabling the efficient and effective operation of pneumatic tools and equipment. Here’s a detailed explanation of how gas air compressors are used in construction projects:

1. Powering Pneumatic Tools:

Gas air compressors are commonly used to power a wide range of pneumatic tools on construction sites. These tools include jackhammers, nail guns, impact wrenches, concrete breakers, air drills, sanders, grinders, and paint sprayers. The compressed air generated by the gas air compressor provides the necessary force and power for efficient operation of these tools, enabling tasks such as concrete demolition, fastening, surface preparation, and finishing.

2. Air Blow and Cleaning Operations:

In construction projects, there is often a need to clean debris, dust, and dirt from work areas, equipment, and surfaces. Gas air compressors are used to generate high-pressure air for air blow and cleaning operations. This helps maintain cleanliness, remove loose materials, and prepare surfaces for further work, such as painting or coating.

3. Operating Pneumatic Systems:

Gas air compressors are employed to operate various pneumatic systems in construction projects. These systems include pneumatic control devices, pneumatic cylinders, and pneumatic actuators. Compressed air from the gas air compressor is used to control the movement of equipment, such as gates, doors, and barriers, as well as to operate pneumatic lifts, hoists, and other lifting mechanisms.

4. Concrete Spraying and Shotcreting:

Gas air compressors are utilized in concrete spraying and shotcreting applications. Compressed air is used to propel the concrete mixture through a nozzle at high velocity, ensuring proper adhesion and distribution on surfaces. This technique is commonly employed in applications such as tunnel construction, slope stabilization, and repair of concrete structures.

5. Sandblasting and Surface Preparation:

In construction projects that require surface preparation, such as removing old paint, rust, or coatings, gas air compressors are often used in conjunction with sandblasting equipment. Compressed air powers the sandblasting process, propelling abrasive materials such as sand or grit onto the surface to achieve effective cleaning and preparation before applying new coatings or finishes.

6. Tire Inflation and Equipment Maintenance:

Gas air compressors are utilized for tire inflation and equipment maintenance on construction sites. They provide compressed air for inflating and maintaining proper tire pressure in construction vehicles and equipment. Additionally, gas air compressors are used for general equipment maintenance, such as cleaning, lubrication, and powering pneumatic tools for repair and maintenance tasks.

7. Portable and Remote Operations:

Gas air compressors are particularly beneficial in construction projects where electricity may not be readily available or feasible. Portable gas air compressors provide the flexibility to operate in remote locations, allowing construction crews to utilize pneumatic tools and equipment without relying on a fixed power source.

Gas air compressors are an integral part of construction projects, facilitating a wide range of tasks and enhancing productivity. Their ability to power pneumatic tools, operate pneumatic systems, and provide compressed air for various applications makes them essential equipment in the construction industry.

.webp)

Can Gas Air Compressors Be Used for Natural Gas Compression?

Gas air compressors are not typically used for natural gas compression. Here’s a detailed explanation:

1. Different Compressed Gases:

Gas air compressors are specifically designed to compress atmospheric air. They are not typically designed or suitable for compressing natural gas. Natural gas, which is primarily composed of methane, requires specialized compressors designed to handle the unique properties and characteristics of the gas.

2. Safety Considerations:

Natural gas compression involves handling a flammable and potentially hazardous substance. Compressing natural gas requires specialized equipment that meets stringent safety standards to prevent leaks, minimize the risk of ignition or explosion, and ensure the safe handling of the gas. Gas air compressors may not have the necessary safety features or materials to handle natural gas safely.

3. Equipment Compatibility:

Natural gas compression systems typically include components such as gas compressors, gas coolers, separators, and control systems that are specifically designed and engineered for the compression and handling of natural gas. These components are built to withstand the specific demands and conditions associated with natural gas compression, including the high pressures and potential presence of impurities.

4. Efficiency and Performance:

Compressing natural gas requires specialized compressors that can handle the high-pressure ratios and volumetric flow rates associated with the gas. Gas air compressors are generally not designed to achieve the same compression ratios and performance levels required for natural gas compression. Using gas air compressors for natural gas compression would likely result in inefficient operation and suboptimal performance.

5. Regulatory Compliance:

Compressing natural gas is subject to various regulations and standards to ensure safety, environmental protection, and compliance with industry guidelines. These regulations often dictate specific requirements for equipment, materials, and operating procedures in natural gas compression systems. Gas air compressors may not meet these regulatory requirements for natural gas compression.

6. Industry Standards and Practices:

The natural gas industry has well-established standards and best practices for equipment selection, installation, and operation in gas compression systems. These standards are based on the specific requirements and characteristics of natural gas. Gas air compressors do not align with these industry standards and practices, which are essential for safe and efficient natural gas compression.

In summary, gas air compressors are not suitable for natural gas compression. Natural gas compression requires specialized equipment designed to handle the unique properties and safety considerations associated with the gas. Compressors specifically engineered for natural gas compression offer the necessary performance, safety features, and regulatory compliance required for efficient and reliable operation in natural gas compression systems.

.webp)

Are There Different Types of Gas Air Compressors Available?

Yes, there are different types of gas air compressors available, each designed to suit specific applications and requirements. These different types vary in terms of design, power source, configuration, and intended use. Here’s a detailed explanation of the various types of gas air compressors:

1. Reciprocating Gas Air Compressors:

Reciprocating gas air compressors, also known as piston compressors, use a reciprocating motion of one or more pistons to compress the air. These compressors are commonly used for small to medium-scale applications and are available in both single-stage and two-stage configurations. Single-stage compressors compress the air in a single stroke, while two-stage compressors use an additional cylinder for further compression, resulting in higher pressures.

2. Rotary Screw Gas Air Compressors:

Rotary screw gas air compressors utilize two interlocking helical screws to compress the air. These compressors are known for their continuous and efficient operation, making them suitable for demanding industrial applications. They are often used in industries such as manufacturing, construction, and automotive where a constant supply of compressed air is required.

3. Rotary Vane Gas Air Compressors:

Rotary vane gas air compressors use a rotor with sliding vanes to compress the air. As the rotor rotates, the vanes slide in and out, creating compression chambers that compress the air. These compressors are compact, reliable, and often used for smaller-scale applications or in situations where space is limited.

4. Centrifugal Gas Air Compressors:

Centrifugal gas air compressors operate by accelerating the air using a high-speed impeller. The accelerated air is then redirected into a diffuser, which converts the velocity energy into pressure energy. These compressors are commonly used for large-scale applications requiring high volumes of compressed air, such as in power plants, refineries, or chemical processing industries.

5. Oil-Free Gas Air Compressors:

Oil-free gas air compressors are designed to provide clean, oil-free compressed air. They feature special sealing mechanisms and materials to prevent oil contamination in the compressed air. These compressors are commonly used in industries where oil-free air is essential, such as food and beverage processing, pharmaceuticals, electronics manufacturing, and painting applications.

6. Portable Gas Air Compressors:

Portable gas air compressors are specifically designed for mobility and ease of transportation. These compressors often feature wheels, handles, or trailers for convenient movement. They are commonly used in construction sites, remote job locations, outdoor events, or other situations where compressed air is needed at different locations.

7. High-Pressure Gas Air Compressors:

High-pressure gas air compressors are designed to generate compressed air at elevated pressures. These compressors are used in applications that require air pressure higher than the standard range, such as in diving operations, breathing air systems, or specialized industrial processes.

8. Biogas Air Compressors:

Biogas air compressors are specifically designed to compress biogas, which is generated from the decomposition of organic matter. These compressors are used in biogas production facilities, landfills, wastewater treatment plants, or agricultural operations where biogas is produced and utilized as an energy source.

These are just a few examples of the different types of gas air compressors available. Each type has its own advantages and is suitable for specific applications based on factors such as required airflow, pressure, mobility, oil-free operation, and environmental considerations. It’s important to choose the appropriate type of gas air compressor based on the specific needs of the application to ensure optimal performance and efficiency.

<img src="https://img.hzpt.com/img/air-compressor/air-compressor-L1.webp" alt="China wholesaler Convenient Energy Saving 100L 3HP Liter Air Compressor Tire Car Industrial Large Belt Gas Air Compressor in China air compressor portable”><img src="https://img.hzpt.com/img/air-compressor/air-compressor-L2.webp" alt="China wholesaler Convenient Energy Saving 100L 3HP Liter Air Compressor Tire Car Industrial Large Belt Gas Air Compressor in China air compressor portable”>

editor by lmc 2024-09-09

China Best Sales 20HP 15kw Gas Powered Inverter CHINAMFG Rotary Screw Air Compressor for Welding with Best Sales

China Best Sales 20HP 15kw Gas Powered Inverter Rotary Screw Air Compressor for Welding

Product Description

The China Best Sales 20HP 15kw Gas Powered Inverter Rotary Screw Air Compressor for Welding is a high-quality and efficient compressor designed for welding applications. With its powerful 20HP/15kw motor, it ensures a steady air flow and working pressure for optimal performance.

TECHNICAL DATA:

|

Model |

WZS-20EVA |

|

Air Flow/Working pressure |

2.2m3/min @ 8bar |

|

1.8m3/min @ 10bar |

|

|

Cooling type of COMPRESSOR |

Air cooling |

|

Cooling type of MOTOR |

Oil cooling |

|

Driven method |

Integrated connection |

|

Start way |

Soft VSD Start |

|

VSD inverter |

INOVANCE / HOLIP / VEICHI |

|

Exhaust Temp. |

< ambient temp. +8 degrees |

|

Oil content |

<2ppm |

|

Noise |

63±2 dB(A) |

|

Power |

380VAC/3ph/0~200Hz |

|

Motor power |

15kW/20hp |

|

Dimension |

1300*860*1030mm |

|

Weight |

480kg |

For more information about this product, please visit our website or contact our sales team.

FAQs

- Q: What is the power supply requirement for this air compressor?

- Q: What is the noise level of this compressor?

- Q: Is this air compressor suitable for welding applications?

- Q: Can I customize the dimensions of this compressor?

- Q: Does this compressor come with a warranty?

A: The air compressor requires a power supply of 380VAC/3ph/0~200Hz.

A: The noise level of this compressor is 63±2 dB(A).

A: Yes, this air compressor is specifically designed for welding applications.

A: Unfortunately, the dimensions of this compressor cannot be customized.

A: Yes, this compressor comes with a standard warranty. Please contact our sales team for more details.

Disclaimer: All content on this page is sourced from the Internet and is provided solely as a reference for product selection. Our products are replacement parts and are not original spare parts. We do not hold the original trademark of the content. However, our replacement parts are designed to perfectly fit the original spare parts. If you require original spare parts, please contact the respective original factory or supplier.

To explore our other product offerings, please visit our website. EVER-POWER GROUP is a leading supplier of various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service. We also offer customization services for drawings and samples. Contact us today to learn more!

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Gas Powered Air Compressor

A gas powered air compressor has several performance characteristics that make it highly desirable:

1. High Power Output

The gas powered air compressor is known for its high power output. It is capable of delivering a significant amount of compressed air, making it suitable for heavy-duty applications.

2. Portability

One of the key advantages of a gas powered air compressor is its portability. Unlike electric air compressors that require a power source, a gas powered compressor can be used in remote locations without access to electricity.

3. Versatility

Gas powered air compressors are highly versatile and can be used for various applications. They are commonly used in construction sites, utility and municipal maintenance, automotive repair and service, emergency services, and boating and marine applications.

4. Durability

Gas powered air compressors are built to withstand harsh environments and heavy usage. They are often made with durable materials that can withstand demanding conditions.

5. Faster Refilling

Compared to electric air compressors, gas powered compressors have faster refilling times, allowing for increased productivity.

Types and Characteristics of Gas Powered Air Compressor

Gas powered air compressors come in different types and each has its own characteristics:

1. Portable Gas Powered Air Compressors

Portable gas powered air compressors are designed for easy transportation and are ideal for on-the-go applications.

2. Stationary Gas Powered Air Compressors

Stationary gas powered air compressors are designed for fixed installations and provide a continuous source of compressed air.

3. Single-Stage Gas Powered Air Compressors

Single-stage gas powered air compressors have a single piston that compresses the air to the desired pressure.

4. Two-Stage Gas Powered Air Compressors

Two-stage gas powered air compressors have two pistons that work in tandem to compress the air, providing higher pressure and efficiency.

Advantages of Gas Powered Air Compressor Made of Different Materials

The choice of material for a gas powered air compressor can affect its performance and durability:

1. Cast Iron Gas Powered Air Compressor

Gas powered air compressors made of cast iron are known for their durability and longevity. They can withstand high temperatures and heavy usage.

2. Aluminum Gas Powered Air Compressor

Gas powered air compressors made of aluminum are lightweight and corrosion-resistant, making them suitable for portable applications.

3. Steel Gas Powered Air Compressor

Steel gas powered air compressors offer strength and ruggedness, making them suitable for heavy-duty applications.

4. Composite Gas Powered Air Compressor

Gas powered air compressors made of composite materials are lightweight and resistant to rust and corrosion. They are often used in applications where portability is important.

Application of Gas Powered Air Compressor

Gas powered air compressors find value and importance in various fields:

1. Construction Sites

Gas powered air compressors are widely used in construction sites for tasks such as powering pneumatic tools, equipment, and machinery.

2. Utility and Municipal Maintenance

Gas powered air compressors play a crucial role in utility and municipal maintenance, allowing for efficient operation of pneumatic systems, maintenance of pipelines, and more.

3. Automotive Repair and Service

Automotive repair and service centers rely on gas powered air compressors to power pneumatic tools, inflate tires, and perform various tasks.

4. Emergency Services

Gas powered air compressors are essential for emergency services such as firefighting, where they power rescue tools and equipment.

5. Boating and Marine Applications

Gas powered air compressors are used in boating and marine applications for tasks such as filling scuba tanks, inflating boat fenders, and operating pneumatic tools.

Future Development Trends and Opportunities of Gas Powered Air Compressor Products

The gas powered air compressor industry is poised for growth and presents several development prospects:

1. Advancements in Technology

Continued advancements in technology will lead to more efficient and powerful gas powered air compressors.

2. Increased Demand for Portable Solutions

As industries become more mobile, the demand for portable gas powered air compressors is expected to rise.

3. Growing Industrial and Construction Sectors

The growth of industrial and construction sectors worldwide will drive the demand for gas powered air compressors in various applications.

4. Focus on Energy Efficiency

Fuel efficiency and reduced emissions will be key areas of focus for the gas powered air compressor industry.

How to Choose a Suitable Gas Powered Air Compressor

Choosing the right gas powered air compressor requires careful consideration:

1. Clear Requirements

Identify your specific needs and requirements in terms of power output, portability, and application.

2. Material Selection

Consider the advantages and characteristics of different materials used in gas powered air compressors, such as cast iron, aluminum, steel, and composite.

3. Design Optimization

Look for features that enhance performance, durability, and ease of use, such as dual-stage compression, oil lubrication, and sturdy construction.

4. Suppliers and After-Sales Service

Choose reliable suppliers that offer good after-sales service, warranty, and support.

5. Cost-Effectiveness

Consider the initial cost, maintenance requirements, and long-term value of the gas powered air compressor.

6. Quality Control

Ensure that the gas powered air compressor meets industry standards and has undergone proper quality control measures.

Author: Dream

China manufacturer High Capacity Compressor High Automation 450kw Gas Powered Compressor Cyclopropane Piston Compressor with High Quality best air compressor

China Manufacturer High Capacity Compressor High Automation 450KW Gas Powered Compressor Cyclopropane Piston Compressor with High Quality Best Air Compressor

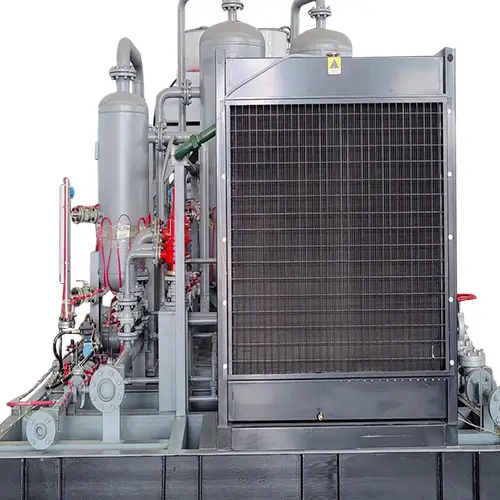

Product Description

This high capacity compressor features high automation and is powered by a gas engine. With a power output of 450KW, it is capable of efficient and reliable performance. The compressor is designed with a cyclopropane piston compressor, ensuring high quality and durability.

Detailed Photos

Product Descriptions:

Mainly used for boosting and transporting natural gas into the pipeline network (natural gas extraction from pipelines, recovery and change of combustible gases). It can also be used for stirring in the pharmaceutical and brewing industries, pressurized gas transportation in the chemical industry, blow molding for bottle production in the food industry, and dust removal from parts in machinery manufacturing.

Advantages:

Our products, incorporating technology from Austria’s LMF and Germany’s CHINAMFG Demag companies, exhibit high reliability. Wearable parts like gas valves and piston rings use products from Austria’s Hoerbiger company, with a lifespan exceeding 8000 hours. The system supports soft starting, allowing frequent start and stop cycles for the compressor. It features a wide intake range for broad adaptability. The overall skid-mounted structure results in low noise and is easy to install in urban areas, leading to investment savings. It is equipped with a CHINAMFG PLC control system for high automation, ABB soft start (or variable frequency), and features automatic shutdown with audible and visual alarms in case of faults.

Product Parameters

| Model | Flow (m3/h) | Inlet Pressure (Mpa) | Outlet Pressure (Mpa) | Weight (Kg) | Power (Kw) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| VW-6/16-24 | 360 | 1.6 | 2.4 | 2600 | 110 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| VW-6/(0-1.62)-(5-21) | 360 | 0-0.162 | 0.5-2.1 | 2350 | 75 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WW-26.7/0.5-10 | 1602 | 0.05 | 1 | 4500 | 250 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DW-2/0.2-16 | 120 | 0.02 | 1.6 | 1500 | 22 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WW-3/8 | 180 | normal pressure | 0.8 | 1500 | 22 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2VW-50/3.5 | 3000 | normal pressure | 0.35 | 6000 | 220 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2VW-16.7/0.5-20 | 1002 | 0.05 | 2 | 6500 | 185 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ZW-0.6/6-10 | 36 | 0.6 | 1 | 760 | 5.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ZW-0.8/12 | 48 | normal pressure | 1.2 | 1200 | 7.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DW-9.5/7 | 570 | normal pressure | 0.7 | 2600 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| VW-4.5/0.5-10 | 270 | 0.05 | 1 | 2100 | 37 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2VW-25/25 | 1500 | normal pressure | 2.5 | 2100 | 250 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2VW-50/3.5 | 3000 | normal pressure |

| Model | WZS-180EVA |

| Air Flow/Working pressure | 22m3/min @ 8bar |

| 20.1m3/min @ 10bar | |

| Cooling type of COMPRESSOR | Air cooling |

| Cooling type of MOTOR | Oil cooling |

| Driven method | Integrated connection |

| Start way | Soft VSD Start |

| VSD inverter | INOVANCE / HOLIP / VEICHI |

| Exhaust Temp. | Ambient temp. +8 degrees |

| Oil content | <2ppm |

| Noise | 72±2 dB(A) |

| Power | 380VAC/3ph/0~200Hz |

| Motor power | 132kW/180hp |

| Dimension | 2550*1650*1850mm |

| Weight | 2880kg |

For more detailed specifications and information about the China Manufacturer 180HP 132kw Gas Powered Inverter Rotary Screw Air Compressor for Welding, please click the button below.

At EVER-POWER GROUP, we offer a wide range of industrial products tailored for various applications. Our product lineup includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are dedicated to providing high-quality products at competitive prices, along with excellent customer service. We welcome customizations and can work with drawings and samples to meet your specific requirements.

FAQs:

1. Is the China Manufacturer 180HP 132kw Gas Powered Inverter Rotary Screw Air Compressor suitable for large-scale welding operations?

Yes, the compressor’s powerful motor and high air flow make it ideal for large-scale welding applications.

2. Does the air compressor come with a warranty?

Yes, we provide a warranty for the China Manufacturer 180HP 132kw Gas Powered Inverter Rotary Screw Air Compressor. Please contact our customer service for more details.

3. Can the compressor be used in different working environments?

Yes, the air compressor is designed with air cooling for the compressor and oil cooling for the motor, allowing it to perform efficiently in various working environments.

4. How can I customize the product to meet my specific requirements?

You can provide us with your drawings or samples, and our team will work closely with you to customize the China Manufacturer 180HP 132kw Gas Powered Inverter Rotary Screw Air Compressor according to your needs.

5. Where can I purchase the China Manufacturer 180HP 132kw Gas Powered Inverter Rotary Screw Air Compressor?

You can contact our sales team or visit our website to place an order for the air compressor. We will ensure a smooth purchasing process and timely delivery of the product.

All content on the page comes from the Internet. The content is only used as a reference for product selection. Our products are replacement parts rather than original spare parts; we are not the holders of the original trademark of the content, and our products are only suitable for after-sales replacement parts, not original spare parts. Our replacement parts can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory or supplier.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Gas Powered Air Compressor

A gas powered air compressor has several performance characteristics that make it highly desirable:

1. High Power Output

The gas powered air compressor is known for its high power output. It is capable of delivering a significant amount of compressed air, making it suitable for heavy-duty applications.

2. Portability

One of the key advantages of a gas powered air compressor is its portability. Unlike electric air compressors that require a power source, a gas powered compressor can be used in remote locations without access to electricity.

3. Versatility

Gas powered air compressors are highly versatile and can be used for various applications. They are commonly used in construction sites, utility and municipal maintenance, automotive repair and service, emergency services, and boating and marine applications.

4. Durability

Gas powered air compressors are built to withstand harsh environments and heavy usage. They are often made with durable materials that can withstand demanding conditions.

5. Faster Refilling

Compared to electric air compressors, gas powered compressors have faster refilling times, allowing for increased productivity.

Types and Characteristics of Gas Powered Air Compressor

Gas powered air compressors come in different types and each has its own characteristics:

1. Portable Gas Powered Air Compressors

Portable gas powered air compressors are designed for easy transportation and are ideal for on-the-go applications.

2. Stationary Gas Powered Air Compressors

Stationary gas powered air compressors are designed for fixed installations and provide a continuous source of compressed air.

3. Single-Stage Gas Powered Air Compressors

Single-stage gas powered air compressors have a single piston that compresses the air to the desired pressure.

4. Two-Stage Gas Powered Air Compressors

Two-stage gas powered air compressors have two pistons that work in tandem to compress the air, providing higher pressure and efficiency.

Advantages of Gas Powered Air Compressor Made of Different Materials

The choice of material for a gas powered air compressor can affect its performance and durability:

1. Cast Iron Gas Powered Air Compressor

Gas powered air compressors made of cast iron are known for their durability and longevity. They can withstand high temperatures and heavy usage.

2. Aluminum Gas Powered Air Compressor

Gas powered air compressors made of aluminum are lightweight and corrosion-resistant, making them suitable for portable applications.

3. Steel Gas Powered Air Compressor

Steel gas powered air compressors offer strength and ruggedness, making them suitable for heavy-duty applications.

4. Composite Gas Powered Air Compressor

Gas powered air compressors made of composite materials are lightweight and resistant to rust and corrosion. They are often used in applications where portability is important.

Application of Gas Powered Air Compressor

Gas powered air compressors find value and importance in various fields:

1. Construction Sites

Gas powered air compressors are widely used in construction sites for tasks such as powering pneumatic tools, equipment, and machinery.

2. Utility and Municipal Maintenance

Gas powered air compressors play a crucial role in utility and municipal maintenance, allowing for efficient operation of pneumatic systems, maintenance of pipelines, and more.

3. Automotive Repair and Service

Automotive repair and service centers rely on gas powered air compressors to power pneumatic tools, inflate tires, and perform various tasks.

4. Emergency Services

Gas powered air compressors are essential for emergency services such as firefighting, where they power rescue tools and equipment.

5. Boating and Marine Applications

Gas powered air compressors are used in boating and marine applications for tasks such as filling scuba tanks, inflating boat fenders, and operating pneumatic tools.

Future Development Trends and Opportunities of Gas Powered Air Compressor Products

The gas powered air compressor industry is poised for growth and presents several development prospects:

1. Advancements in Technology

Continued advancements in technology will lead to more efficient and powerful gas powered air compressors.

2. Increased Demand for Portable Solutions

As industries become more mobile, the demand for portable gas powered air compressors is expected to rise.

3. Growing Industrial and Construction Sectors

The growth of industrial and construction sectors worldwide will drive the demand for gas powered air compressors in various applications.

4. Focus on Energy Efficiency

Fuel efficiency and reduced emissions will be key areas of focus for the gas powered air compressor industry.

How to Choose a Suitable Gas Powered Air Compressor

Choosing the right gas powered air compressor requires careful consideration:

1. Clear Requirements

Identify your specific needs and requirements in terms of power output, portability, and application.

2. Material Selection

Consider the advantages and characteristics of different materials used in gas powered air compressors, such as cast iron, aluminum, steel, and composite.

3. Design Optimization

Look for features that enhance performance, durability, and ease of use, such as dual-stage compression, oil lubrication, and sturdy construction.

4. Suppliers and After-Sales Service

Choose reliable suppliers that offer good after-sales service, warranty, and support.

5. Cost-Effectiveness

Consider the initial cost, maintenance requirements, and long-term value of the gas powered air compressor.

6. Quality Control

Ensure that the gas powered air compressor meets industry standards and has undergone proper quality control measures.

Author: Dream

China Standard High-Efficient C3h6 50nm3/Min High Capacity Compressor High Automation 450kw Gas Powered Compressor Cyclopropane Piston Compressor air compressor CHINAMFG freight

China Standard High-Efficient C3h6 50nm3/Min High Capacity Compressor High Automation 450kw Gas Powered Compressor Cyclopropane Piston Compressor air compressor

Product Description

Introducing our high-efficient C3H6 50Nm3/min high capacity compressor with high automation. This gas-powered compressor is designed with a cyclopropane piston compressor, making it ideal for boosting and transporting natural gas into the pipeline network. It is also suitable for various applications, including stirring in the pharmaceutical and brewing industries, pressurized gas transportation in the chemical industry, blow molding for bottle production in the food industry, and dust removal from parts in machinery manufacturing.

Product Advantages

Our products are built with advanced technology from Austria’s LMF and Germany’s CHINAMFG Demag companies, ensuring high reliability. The wearable parts, such as gas valves and piston rings, are sourced from Austria’s Hoerbiger company, providing a lifespan exceeding 8000 hours. This compressor features a soft starting system, allowing for frequent start and stop cycles. Its wide intake range ensures adaptability to various conditions. The overall skid-mounted structure reduces noise and facilitates easy installation in urban areas, resulting in cost savings. Equipped with a CHINAMFG PLC control system, it offers high automation and is complemented by ABB soft start (or variable frequency) technology. In case of faults, the compressor has an automatic shutdown system with audible and visual alarms.

Product Parameters

| Model | Flow (m3/h) | Inlet Pressure (Mpa) | Outlet Pressure (Mpa) | Weight (Kg) | Power (Kw) |

|---|---|---|---|---|---|

| VW-6/16-24 | 360 | 1.6 | 2.4 | 2600 | 110 |

| VW-6/(0-1.62)-(5-21) | 360 | 0-0.162 | 0.5-2.1 | 2350 | 75 |

| WW-26.7/0.5-10 | 1602 | 0.05 | 1 | 4500 | 250 |

| DW-2/0.2-16 | 120 | 0.02 | 1.6 | 1500 | 22 |

| WW-3/8 | 180 | normal pressure | 0.8 | 1500 | 22 |

| 2VW-50/3.5 | 3000 | normal pressure | 0.35 | 6000 | 220 |

Our Factory

Part of Customer Visit

Certifications & Testing

Related Product

EVER-POWER GROUP offers a wide range of high-quality industrial products. Our product lineup includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings. We strive to provide our customers with high-quality products, competitive prices, and excellent services. Customization of drawings and samples is welcome.

FAQ

Q: Are you a factory?

A: Yes, we are indeed a factory. We specialize in manufacturing high-quality Air/Gas Compressors and are proud to be a primary source for these products.

Q: How long is your delivery time?

A: It varies depending on the specific situation. For our standard configuration compressors, the delivery time is around 30 days. For customized compressors, it usually takes about 30-45 days.

Q: What technical support do you offer?

A: We offer comprehensive technical support to our clients, including remote assistance for installation and commissioning processes. Additionally, we have a team of seasoned engineers ready to be deployed to international client locations for meticulous on-site debugging, installation, and post-installation services.

Q: What is your warranty period?

A: Our warranty policy is valid for a period of 18 months from the date of commissioning at the end customer’s site or 21 months from the date of receipt by the purchaser, whichever comes first. This comprehensive coverage is designed to ensure total customer satisfaction and the reliability of our products.

Q: How do you package the compressors?

A: For smaller compressors, we utilize robust plywood boxes that conform to export specifications. For the larger units, we strategically place them in freight containers, implementing secure fastening methods to safeguard against any potential damage during the shipping process.

Q: What are your payment terms?

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Gas Powered Air Compressor

A gas powered air compressor has several performance characteristics that make it highly desirable:

1. High Power Output

The gas powered air compressor is known for its high power output. It is capable of delivering a significant amount of compressed air, making it suitable for heavy-duty applications.

2. Portability

One of the key advantages of a gas powered air compressor is its portability. Unlike electric air compressors that require a power source, a gas powered compressor can be used in remote locations without access to electricity.

3. Versatility

Gas powered air compressors are highly versatile and can be used for various applications. They are commonly used in construction sites, utility and municipal maintenance, automotive repair and service, emergency services, and boating and marine applications.

4. Durability

Gas powered air compressors are built to withstand harsh environments and heavy usage. They are often made with durable materials that can withstand demanding conditions.

5. Faster Refilling

Compared to electric air compressors, gas powered compressors have faster refilling times, allowing for increased productivity.

Types and Characteristics of Gas Powered Air Compressor

Gas powered air compressors come in different types and each has its own characteristics:

1. Portable Gas Powered Air Compressors

Portable gas powered air compressors are designed for easy transportation and are ideal for on-the-go applications.

2. Stationary Gas Powered Air Compressors

Stationary gas powered air compressors are designed for fixed installations and provide a continuous source of compressed air.

3. Single-Stage Gas Powered Air Compressors

Single-stage gas powered air compressors have a single piston that compresses the air to the desired pressure.

4. Two-Stage Gas Powered Air Compressors

Two-stage gas powered air compressors have two pistons that work in tandem to compress the air, providing higher pressure and efficiency.

Advantages of Gas Powered Air Compressor Made of Different Materials

The choice of material for a gas powered air compressor can affect its performance and durability:

1. Cast Iron Gas Powered Air Compressor

Gas powered air compressors made of cast iron are known for their durability and longevity. They can withstand high temperatures and heavy usage.

2. Aluminum Gas Powered Air Compressor

Gas powered air compressors made of aluminum are lightweight and corrosion-resistant, making them suitable for portable applications.

3. Steel Gas Powered Air Compressor

Steel gas powered air compressors offer strength and ruggedness, making them suitable for heavy-duty applications.

4. Composite Gas Powered Air Compressor

Gas powered air compressors made of composite materials are lightweight and resistant to rust and corrosion. They are often used in applications where portability is important.

Application of Gas Powered Air Compressor

Gas powered air compressors find value and importance in various fields:

1. Construction Sites

Gas powered air compressors are widely used in construction sites for tasks such as powering pneumatic tools, equipment, and machinery.

2. Utility and Municipal Maintenance

Gas powered air compressors play a crucial role in utility and municipal maintenance, allowing for efficient operation of pneumatic systems, maintenance of pipelines, and more.

3. Automotive Repair and Service

Automotive repair and service centers rely on gas powered air compressors to power pneumatic tools, inflate tires, and perform various tasks.

4. Emergency Services

Gas powered air compressors are essential for emergency services such as firefighting, where they power rescue tools and equipment.

5. Boating and Marine Applications

Gas powered air compressors are used in boating and marine applications for tasks such as filling scuba tanks, inflating boat fenders, and operating pneumatic tools.

Future Development Trends and Opportunities of Gas Powered Air Compressor Products

The gas powered air compressor industry is poised for growth and presents several development prospects:

1. Advancements in Technology

Continued advancements in technology will lead to more efficient and powerful gas powered air compressors.

2. Increased Demand for Portable Solutions

As industries become more mobile, the demand for portable gas powered air compressors is expected to rise.

3. Growing Industrial and Construction Sectors

The growth of industrial and construction sectors worldwide will drive the demand for gas powered air compressors in various applications.

4. Focus on Energy Efficiency

Fuel efficiency and reduced emissions will be key areas of focus for the gas powered air compressor industry.

How to Choose a Suitable Gas Powered Air Compressor

Choosing the right gas powered air compressor requires careful consideration: